This week, we finally finished our build process and tested the box in location.

Following feedback from last week, we decided that a hexagonal box would be a better option, as it would look more distinctive from a distance and fit more neatly into a user’s hand. We ordered a suitable box from Amazon.

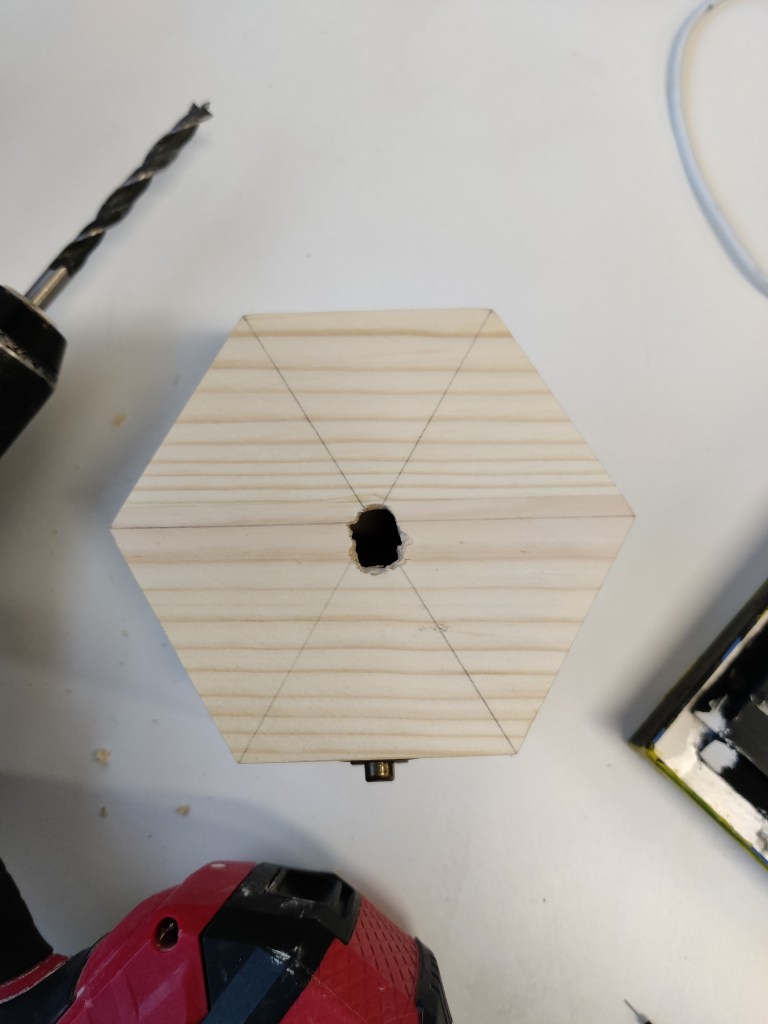

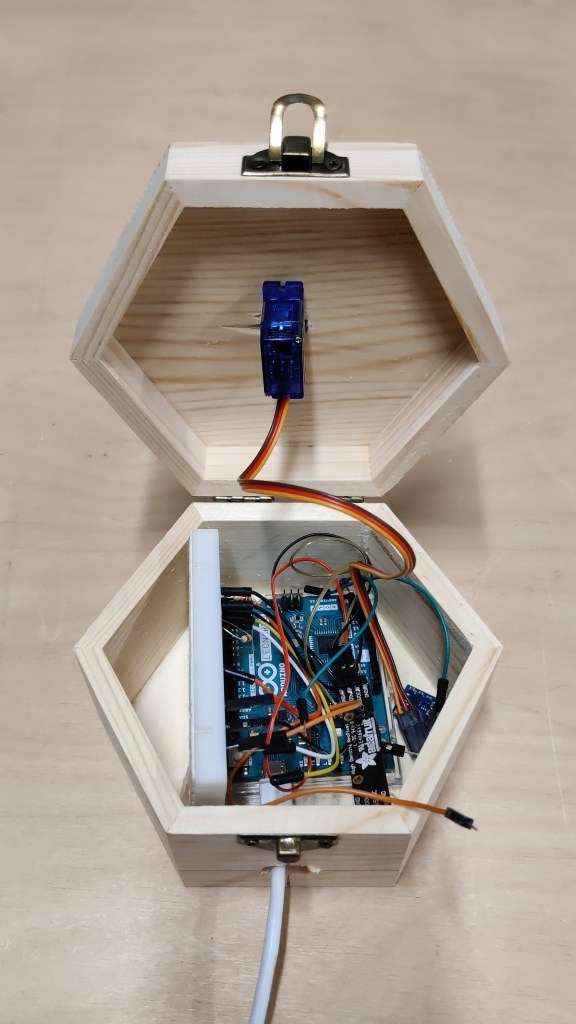

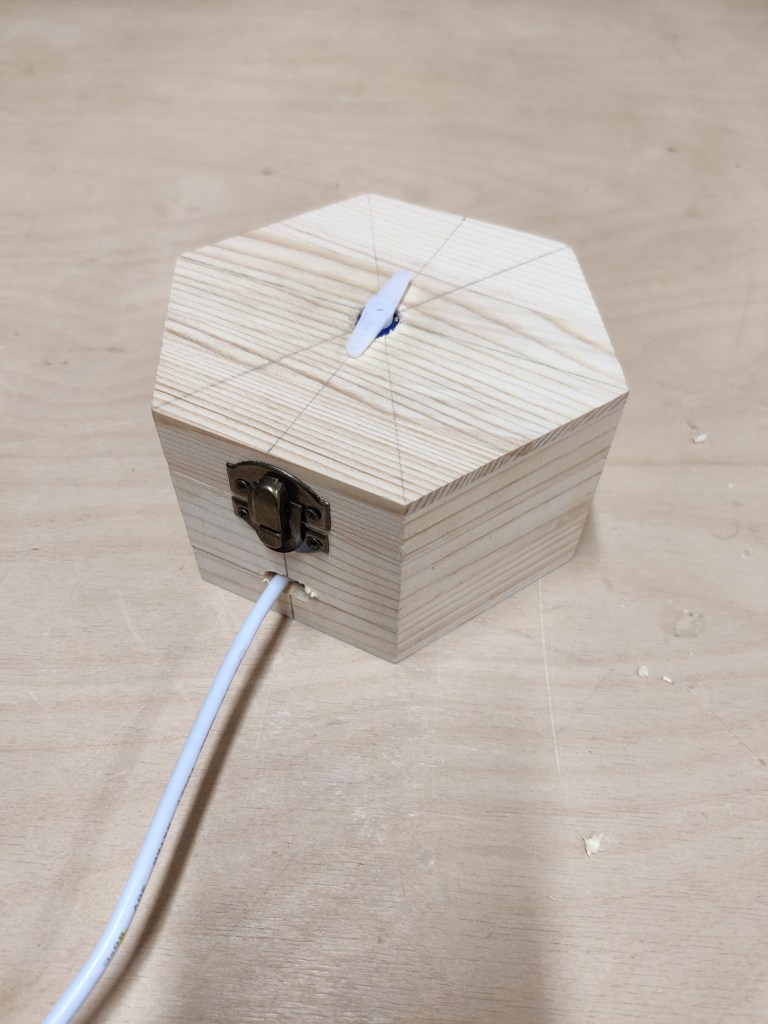

We drilled some rough holes in the box for the compass needle and the power cable. We then mounted the Arduino, breadboard and motor inside the box, and tested that the device worked. At this point, we were working with two boxes in case something went wrong with the drilling.

We then drilled holes to allow the light through and spray painted the box yellow – the spray paint was far easier to apply smoothly than the acrylic paint we used last week.

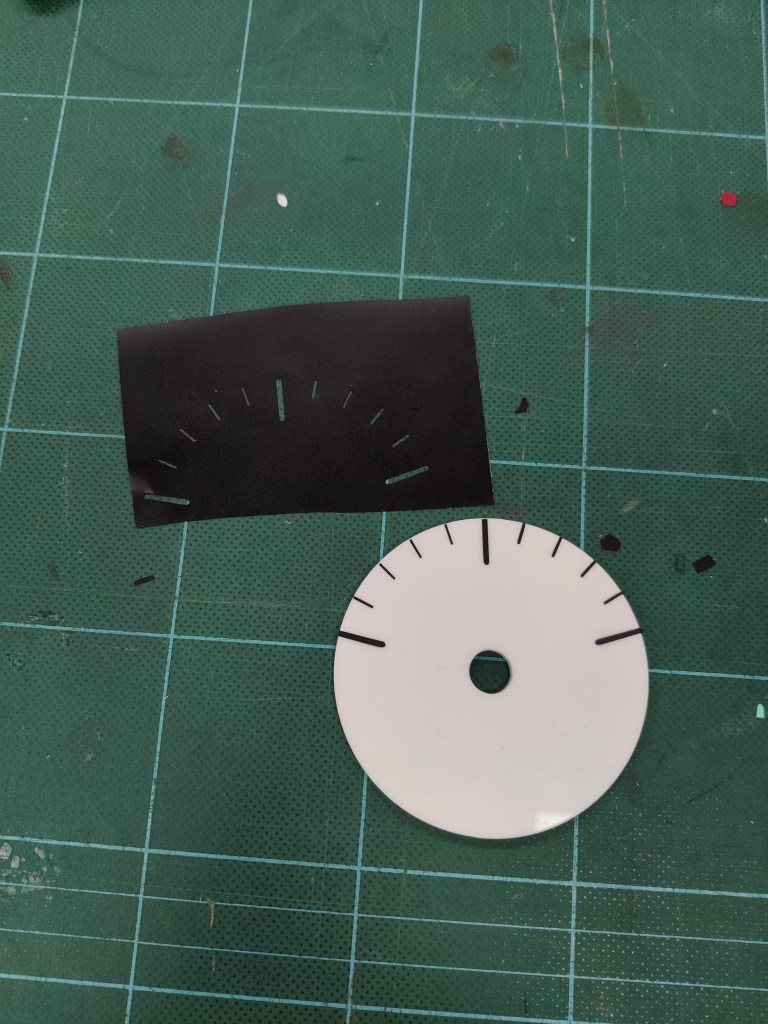

For the compass face, we ordered a white acrylic disc online and vinyl printed tick marks. We originally wanted a more detailed design, but the vinyl cutter was malfunctioning and our first attempts failed.

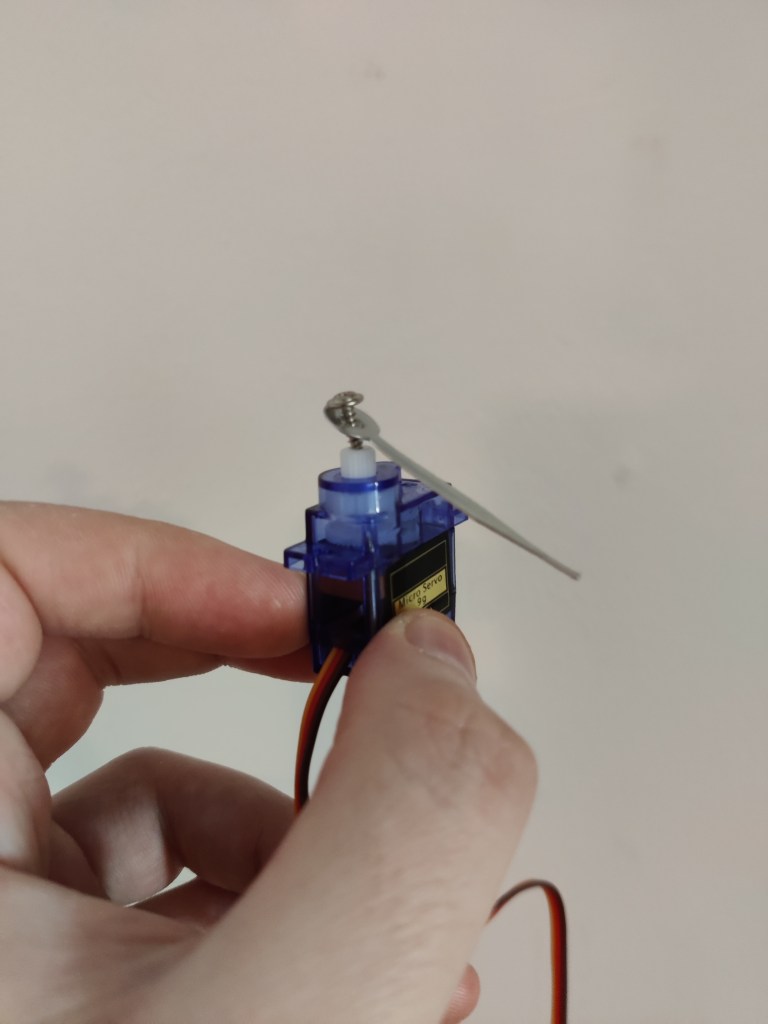

We were unsatisfied with the plastic needle that came with the servo motor, and so we bought a set of replacement clock hands, as we felt it would feed more into the nostalgic and skeuomorphic aesthetics we were aiming for.

Finally, we assembled the whole thing.

To test the compass, we took some participants out in Dalston and asked for feedback.

We got the following feedback:

- Our stickers were easy to spot, even in otherwise busy landscapes

- The use of archival sound footage in our soundscapes was significantly more evocative than the stories on their own

- The box was easy to carry, but the fact that it was wired was frustrating (obviously we are now out of time to rectify this, but in a productised version this could be done by replacing the PC driving it with a battery-powered Raspberry Pi or similar)

Reflection on this week

- I’m once again impressed by how quickly the high-fidelity built came together. With access to help and enough pre-planning, we were able to put a lot together in just a week.

- The hexagonal shape turns the device itself into a satisfying artefact of our work, and I’m glad we were able to improve upon our low-fidelity version.

- While some of the drill holes are rough due to the thin plywood of the box, we didn’t have time to improve the fidelity any more. Given more time devoted to the build process, we could have avoided this by building some or part of the box from scratch out of higher quality materials.

To commemorate the finishing of the project, I combined my reflections on the whole project into one post, which can be found here.